ESK™

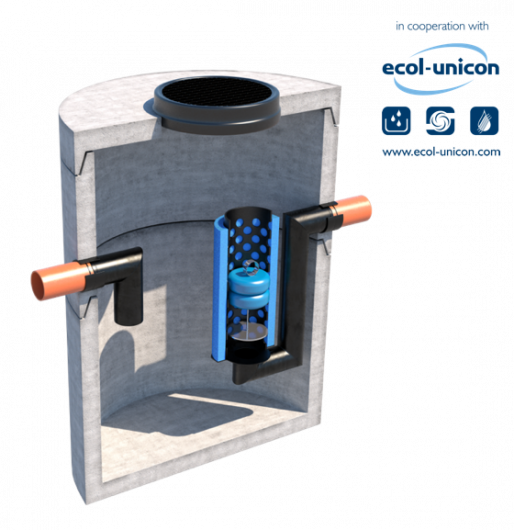

The ESK™ is a passive high efficiency coalescing separator that removes free oil from contaminated stormwater runoff and has a built-in shutoff valve to prevent spills and storage capacity excess exiting the device. The device is ideally suited for sites where specific effluent targets are specified, or for sites where removal of oil and grease is the greatest concern e.g. fuel stations, fuel distribution stations, car servicing workshops.

It is typically sized to remove oil droplets as small as 10 microns and achieve an effluent concentration of 5 mg/L or less.

The ESK™ is a proven technology that meets the European and British EN 858-1:2002 class 1 standard.

How Does It Work?

The design of the separator calms down the flow of polluted water and at the same time forces the division into oil (stored in the separator) and water. Untreated runoff flows enter the ESK™ and is directed downwards via an angled inlet pipe, allowing gravity to start the separation process.

Contact: [email protected] or phone 0800 STORMWATER for more information

VIDEOS / GALLERY

ESK™ KEY FEATURES & BENEFITS:

- Separates free oil from water using gravitational and coalescing technology

- Provides discharge of oil concentration as low as <5 PPM with an oil droplet size of approx. 10 μm

- Standard products accommodate a large variety of flows

- Automatic shutoff valve

- Easy to install and maintain

- Reusable and washable media

- Smaller footprint and depth than traditional oil/water separators

- Optional alarm system

- CE Marking

- Compliant with European and British EN 858 standards